About knitted fabrics

Today this post will cover what knitted fabrics are, types of knitted fabrics, and machines that weave knitted fabrics.

First of all, knitted fabrics are fabrics formed by bending yarns into loops with knitting needles and stringing them over each other. The difference between knitted fabrics and woven fabrics lies in the different forms of yarns in the fabric. Knitting is divided into weft knitted (weft knitted fabric) and warp knitted (warp knitted fabric), knitted fabrics are widely used in apparel fabrics and lining, home textiles and other products, by the majority of consumers.

Weft knitting fabrics are often made of low elasticity polyester yarn or shaped polyester yarn, nylon yarn, cotton yarn, wool yarn, etc., and are knitted on various weft knitting machines by using flat-needle organization, changing flat-needle organization, ribbed flat-needle organization, double-ribbed flat-needle organization, jacquard organization, terry organization, etc. It has more varieties and generally has good elasticity and elongation, firmness and wrinkle resistance, strong woolen sense, and easy to wash and quick drying. It has more varieties, generally have good elasticity and extensibility, fabric soft, firm and wrinkle-resistant, strong sense of wool type, and easy to wash and quick drying. However, its moisture absorption is poor, the fabric is not stiff enough, and easy to disintegrate, crimping, chemical fiber fabrics are easy to hair, pilling, hook silk. There are mainly the following varieties:

1, polyester color woven knitted fabrics: fabric color is bright, beautiful, color and harmony, the texture is close and thick, the weaving pattern is clear, the sense of wool type is strong, there are similar to wool fabric tweed style. Mainly used as men's and women's tops, suits, windbreakers, undershirts, skirts, cotton-padded fabrics, children's clothing and so on;

2, polyester knitted labor fabrics: this fabric is tight and thick, firm and wear-resistant, stiff and elastic, if the raw material with spandex containing core yarn, it can be woven into elastic knitted denim, better elasticity. Mainly used for men's and women's upper pants;

3、Polyester knitted corduroy fabric: the fabric is concave-convex, feel thick and plump, good elasticity and warmth. Mainly used for men's and women's tops, suits, windbreakers, children's clothing and other fabrics;

4, polyester cover cotton knitted fabric: the fabric is dyed for shirts, jackets, sportswear fabrics. The fabric is stiff and wrinkle-resistant, firm and wear-resistant, moisture-absorbent and breathable on one side of the body, soft and comfortable.

5, artificial fur needle fabric: fabric feel thick, soft, good warmth. According to the different varieties, mainly used for coat fabrics, clothing lining, collars, hats and so on. Artificial fur is also useful for warp knitting method of knitting.

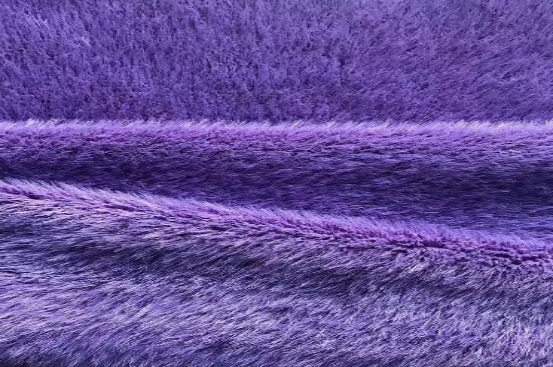

6, velvet knitted fabrics: fabric feel soft, thick, firm and wear-resistant, velvet dense towering, soft color and light. Mainly used as outerwear fabrics, collars or hats with materials. It can also be woven with warp knitting, for example: warp knitting terry shearling fabric;

Warp knitting fabrics are divided into two categories:

One is Raschel fabrics, mainly characterized by larger flower shape, fabric surface is coarse and sparse, more holes, mainly for decorative fabrics;

The second is tricot fabrics, fabric surface is fine and dense, less color, but high yield, mainly for wrapping fabrics and printed fabrics, this kind of fabric is mostly used for chemical fiber filament, otherwise the production efficiency is extremely low!

Often polyester, polyamide, polypropylene, polypropylene and other synthetic filaments as raw materials, but also cotton, wool, silk, linen, chemical fibers and their blended yarns as raw materials for weaving. It has the advantages of good longitudinal dimensional stability, fabric stiffness, small disintegration, will not crimp, good air permeability and so on. However, its lateral extension, elasticity and softness are not as good as weft knitted fabrics. There are mainly the following types:

1, polyester warp knitting fabrics: fabric surface is flat and straight, bright color, there are thick and thin type of points. Thin type is mainly used as shirts, skirts fabrics; thick type, thick type can be used for men and women in clothing, windbreakers, tops, suits, pants and other fabrics;

2, warp knitting pile fabric: mainly used as winter men's and women's coats, trench coats, tops, pants and other fabrics, fabric drape, easy to wash, quick drying, non-iron, but in use static electricity accumulation, easy to adsorb dust;

3, warp knitting mesh fabric: taking the mesh fabric texture light, elasticity and breathability, feel smooth and soft, mainly used as summer men and women's shirt fabric;

4, warp knitting velvet fabric: surface velvet dense towering, feel thick, full, soft, elastic, good warmth, mainly used as winter clothing, children's clothing fabrics;

5, warp knitting terry fabrics: this fabric has a full-bodied feel thick, firm and thick cloth body, elasticity, moisture absorption, good warmth, terry structure is stable, has good taking performance, mainly for sportswear, T-shirts, pajamas, children's clothing and other fabrics.

Here is the process of making knitted fabrics.

1. Knitting process

The production of knitted fabrics first needs to be knitted. The knitting process is generally divided into two kinds of mold machine knitting and warp knitting. Among them, horizontal knitting refers to knitting the yarn through the die direction movement of the knitting machine, common knitting machine, circular knitting machine, etc.; warp knitting refers to knitting the yarn through the longitudinal movement of the knitting machine, common warp knitting machine, shuttle knitting machine and so on.

2. Dyeing process

The knitted fabrics will be dyed. The dyeing process usually includes further washing of the fabric, dyeing, rinsing, stain removal and other steps. Dyeing can be done according to the demand for single-color dyeing, multi-color dyeing, printing and other processing. Different fabric materials on the dyeing process also has requirements, such as cotton, linen fabrics require good color fastness dyeing, woolen fabrics, to water color uniformity

4.Finished product shaping

After the process of chemical finishing fabrics need to be finished shaping. The purpose of finished product shaping is to make the fabric have certain shape stability and size.

The purpose of finished product shaping is to make fabrics have certain shape stability and size stability. Finished product shaping is generally divided into thermal shaping and chemical shaping two kinds. Thermal shaping refers to heating the fabric to a certain temperature, through the principle of thermal expansion and contraction of the fabric to maintain the shape; chemical shaping refers to the addition of chemical substances in the dyeing or finishing treatment, so that the fabric to maintain the shape.

5.Inspection quality process

Finished shaping fabrics need to go through quality inspection. The quality inspection process generally includes appearance quality inspection, physical index inspection, chemical index inspection and so on. According to different fabric materials and uses, the quality standard of the fabric is also different.

6. Packing and storage

After the quality inspection, the fabrics will be packed and put into storage. Packaging is generally based on the characteristics and uses of fabrics, choose the appropriate packaging to ensure that the fabrics are not damaged during transportation and storage.

The above is the production process of knitted fabrics. Through the above process, we can produce knitted fabrics with excellent quality and wide range of uses, which are full of market demand.